Recycled Cable Management Systems

The waste situation

Each year, the UK and Ireland produce an astonishing 130 million tonnes of waste as a by-product of construction activity. This is a considerable amount, in fact, it equates to around 60% of all waste. Unfortunately, a lot of it isn’t considered recyclable and as such, an estimated 25 million tonnes is sent straight to landfill.

Sending so much waste to landfill sites is unsustainable. Some experts have warned of a ‘toxic time-bomb’ facing us, with landfill sites coming under threat from flooding and coastal erosion.

Finding a solution

It’s important to find solutions to the current problem. What’s more, it’s important that the solution is sustainable and beneficial to the broader environment. One of the best approaches is for electrical contractors to begin selecting products that are manufactured from recycled material, and make apprentices entering the industry aware that these products are available. As recycled material is re-used it reduces the amount of waste sent to landfill sites.

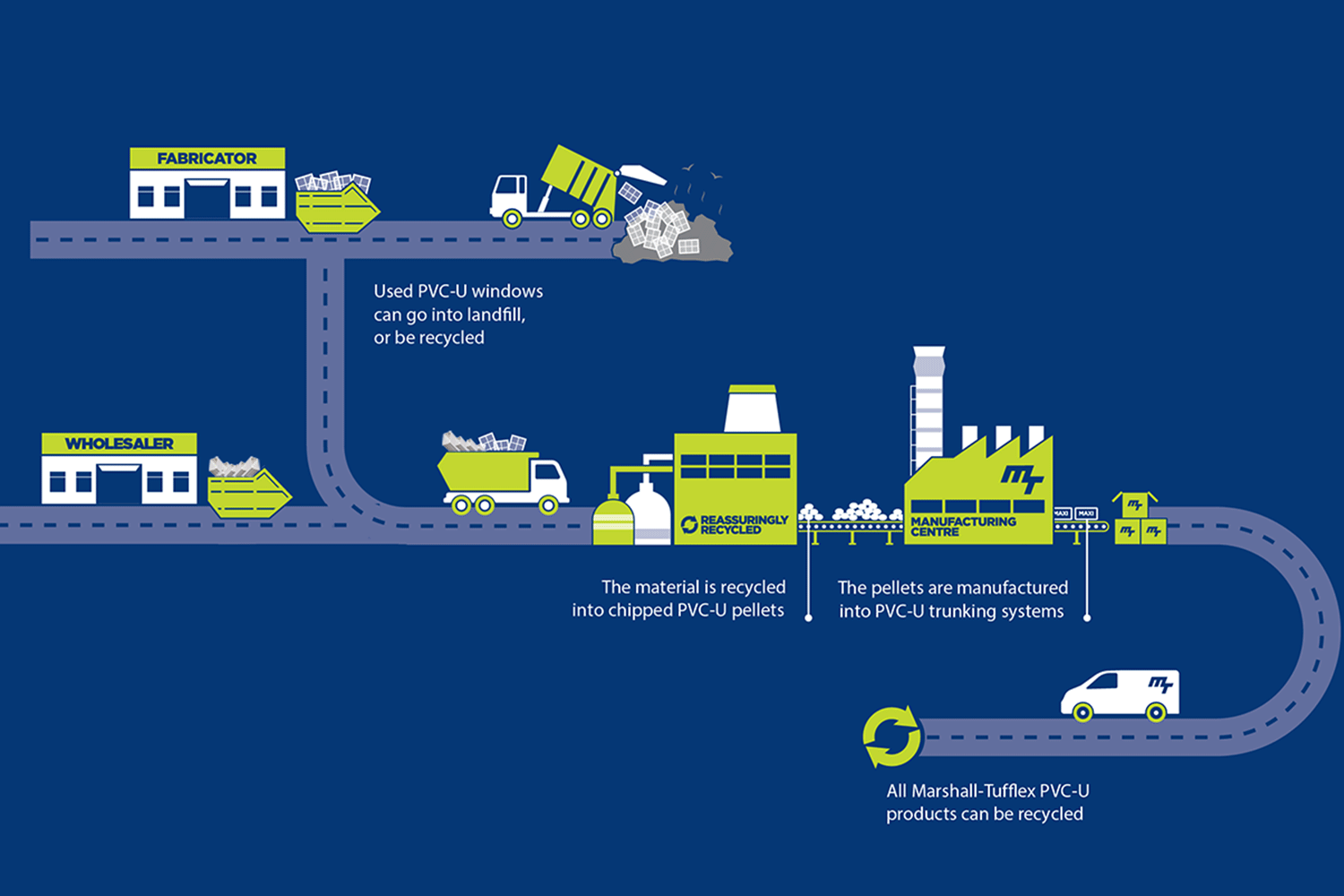

The onus is on manufacturers to help make this solution a reality. Marshall-Tufflex have been using recycled material to manufacture products for more than twenty years. They manufacture their PVC-U trunking using an average of 80% recycled material, with some extruded white trunking profiles manufactured from 100% recycled content.

Their objective is to ensure all PVC-U cable management system products installed in the UK are manufactured from a minimum of 50% recycled material, within a decade.

Building a collective approach

To achieve this goal, we all need to work together. It’s important that the industry adopts a more collective approach. From architect to end-user and from apprentice electrician to the main contractor, it’s time for the entire supply chain to reinvigorate the conversation around sustainability. Whilst the target might sound ambitious, we believe it is achievable.

More than most materials, offcuts from PVC-U window fabrication are ideal for recycling with the material designed to withstand the external environment. As a result, the recycled PVC content is stronger than when the virgin material is used. What’s more, the material can be recycled over 20 times and will still retain its properties.

Recycling isn’t just good for the environment, but it’s also good for business. Not only can firms cut down on waste management costs, but as the recycled material is stronger, it will last longer without needing maintenance. Furthermore, it will mean that companies needn’t worry about finding solutions to the landfill problem.

With some estimates predicting that 200 million tonnes of PVC will come out of European buildings in the next 20 years the time is now to find a solution. For leading manufacturers, this means beginning to enforce strict quality control process to better monitor the quality of the recycled material.

Important regulations

In looking to make these improvements, it is important that manufacturers stay in-line with the Registration, Evaluation, Authorisation and restriction of Chemicals (REACH) standards. It’s also vital that manufacturers comply with the ISO 14000 Family – Environmental Management.

Both standards provide a set of practical tools for companies and organisations looking to manage their environmental responsibilities. Fulfilling the standards help to demonstrate manufacturers have taken steps to reduce their environmental impact. Any firms not complying with the standards need to change.

The Reassuringly Recycled Assurance

We work with Marshall-Tufflex to start a conversation about sustainability in the construction industry. Making Consultant Engineers, Electrical Contractors and Electrical Wholesalers aware of the options will significantly reduce the sector’s environmental impact in the future and contribute towards a more circular economy.

Marshall-Tufflex have pioneered plastic extrusion for over than 75 years. They have led the way in product research, development and innovation, especially when it comes to using recycled material. As a result, they have successfully manufactured cable management system made of recycled PVC-U for over 20 years.

To do so, they use ‘post-industrial waste’ windows (waste windows from window fabricators) or ‘post-consumer waste’ windows (windows that have come out of buildings at the end of their useful life). Because windows are designed to withstand external elements, they obtain a raw material that is more robust and higher quality than virgin PVC.

Hence, when you specify, install and buy our trunking or conduits, you also contribute to reducing your impact on the environment.

Overall, Marshall-Tufflex manufacture their PVC-U products using 80% recycled material. Thereby, they prevented thousands of tonnes of PVC-U windows ending up in landfill.